Custom Process of Industrial Tray Mold

The customization process of industrial tray mold generally includes the following steps:

1. Demand communication: Communicate with customers to determine the size, shape, material and other requirements of the pallets to be made, and understand the customer's use environment and load requirements for pallets.

2. Design: According to customer requirements and use environment, design suitable pallet mold drawings and conduct preliminary confirmation.

3. Making samples: Make samples according to the design drawings, and conduct tests to ensure that the samples meet customer requirements and use environment, and provide them to customers for confirmation.

4. Confirm the drawing: After the customer confirms the sample, the design drawing will be confirmed again according to the sample, and a formal tray mold will be made on this basis.

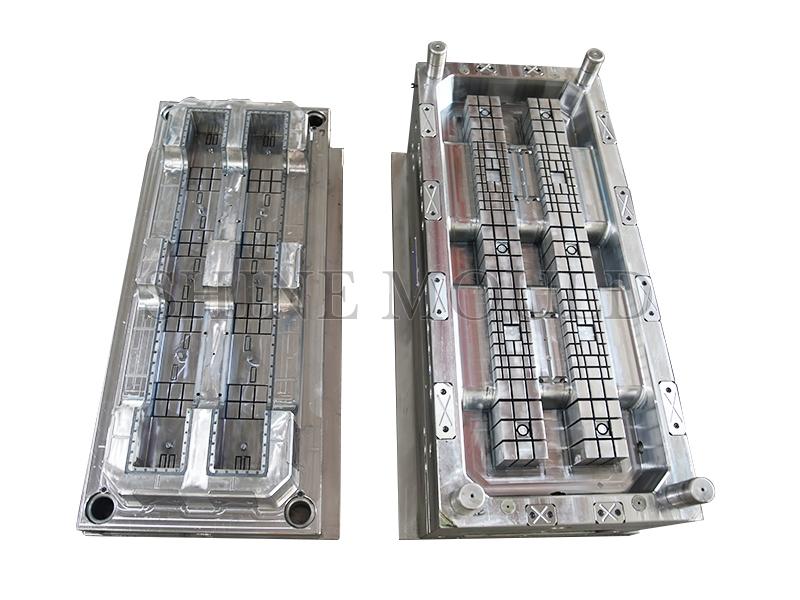

5. Mold making: According to the confirmed design drawings, pallet molds are made, usually using high-precision equipment such as CNC machining centers for processing.

6. Test the mold: After the mold is made, it is necessary to conduct a mold test to ensure that the mold can accurately produce a pallet that meets the customer's requirements.

7. Adjustment and optimization: If the mold is found to have problems during the test, it is necessary to adjust and optimize the mold until it meets the customer's requirements and the use environment.

8. Production: After the mold has been tested and adjusted, it starts to produce pallets. The service life of the mold is basically the same as that of the pallet. Therefore, during the production process, the mold needs to be maintained to prolong its service life.

The above is the customization process of industrial pallet molds. Every step needs to strictly control the quality to ensure that the final pallets produced meet the needs of customers and can be safe and reliable during use.

If you want to know more product details, you can click here: Industrial Pallet Moulds Manufacturers.

Search...

Search... English

English

.jpg?imageView2/2/format/jp2)