Design of Plastic Stool Mould

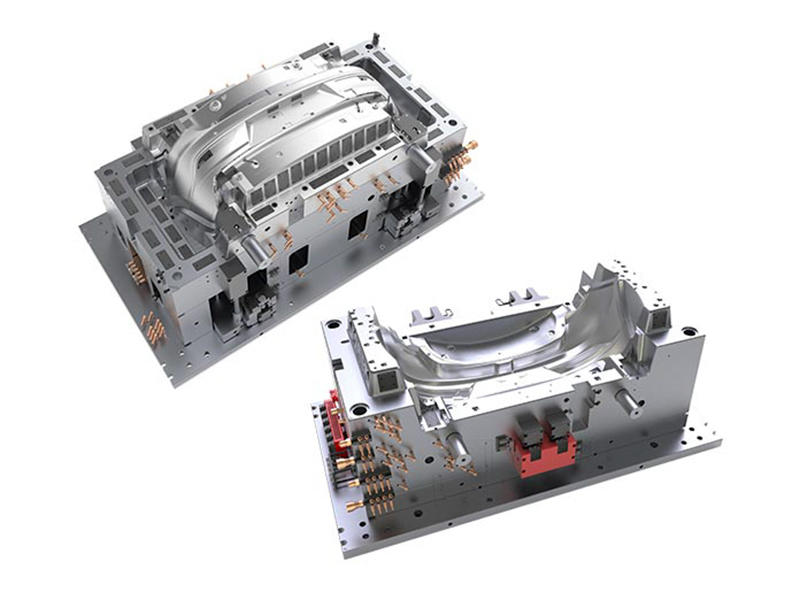

Design for plastic stool mould. Through the process analysis and comparison of plastic parts, the injection mold is finally designed. Starting from the product structure process and specific mold structure, the mold pouring system, mold forming part structure, ejection system, cooling system, injection molding machine selection and related parameter verification are designed in detail, and the mold processing technology is simply compiled.

The entire design process shows that the mold can achieve the required processing technology for plastic parts. The main task is the design of the stool structure and the injection mold, that is, the design of the injection mold for the production of plastic stool plastic products, in order to realize automation and increase the output. According to the specific structure of the plastic basin, the mold is a single parting surface injection mold with a direct gate.

According to the mold structure, a straight guide column is used, and a large demoulding angle is set to facilitate demoulding, and the design of side core pulling is omitted. The mold design shows that the mold can meet the quality and processing requirements of the plastic stool. The advantage is that the mechanism is simplified, the space used for the mold is reduced, and the manufacturing cost of the mold is greatly reduced.

Search...

Search... English

English

.jpg?imageView2/2/format/jp2)