Mold manufacturing technology

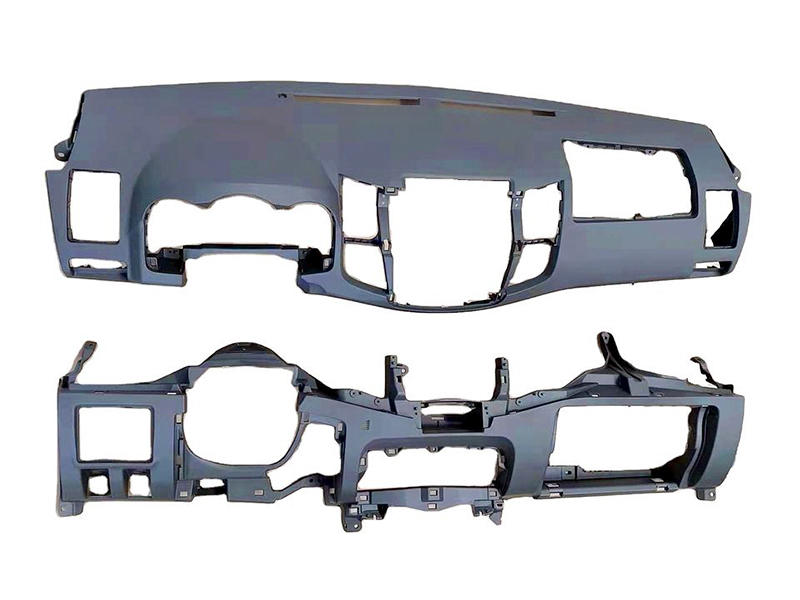

The proportion of plastic parts in auto parts is very large. Due to the advantages of plastic parts such as beautiful appearance, light weight and easy processing, the demand for plastic parts is increasing day by day. The use of plastic can reduce the weight of parts by about 40%, and the cost can be greatly reduced, which makes plastic the preferred material for vehicle lightweighting.

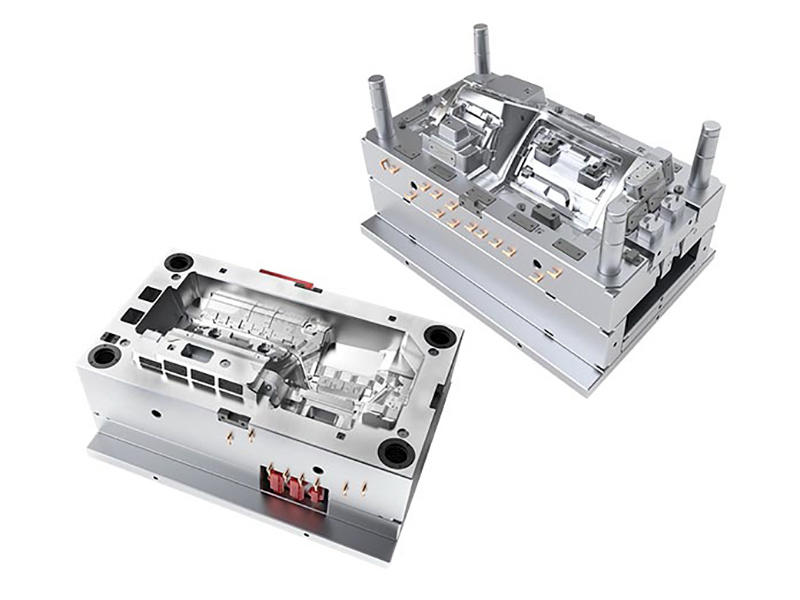

The desired properties of plastics are produced by adding different fillers, plasticizers and hardeners, changing the mechanical strength and processing properties of the material to meet the requirements of different parts of the car. When car companies develop new cars, they need to use hundreds of injection molds, which requires the quality of plastic parts in production to be guaranteed, and the quality of plastic parts is determined by the mold.

Molds have conformal cooling channels used to make complex automotive parts with variable thickness in certain locations. To cool locations with thicker walls, local conformal cooling channels are proposed, where the cooling lines are helical. Conformal cooling channels reduce cycle time by approximately 30% compared to conventional cooling channels.

Search...

Search... English

English

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)