The Core of Car Interiors

Sale China Automotive Instrument panel Mould Supplier Manufacturer

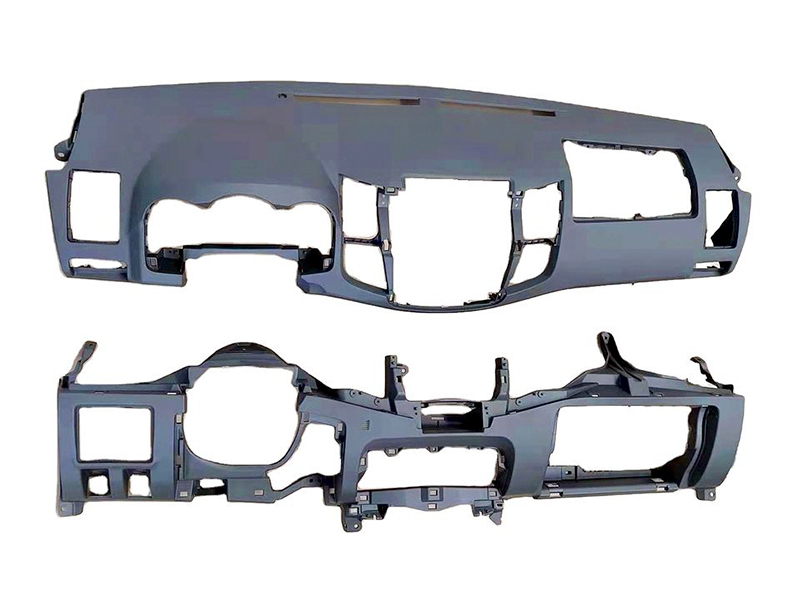

In the automobile manufacturing industry, Automotive Mold Supplier plays a vital role. As a professional Automotive Mold Supplier, we fully understand the importance of the accuracy and quality of each component to the performance of the entire vehicle. Today, I would like to introduce to you a particularly important automotive mold - Instrument panel mold.

Dashboard molds are an integral part of car interiors. It not only carries the function of displaying vehicle information, but also directly affects the driver's operating experience and the aesthetics of the vehicle. As an Automotive Mold Supplier, we understand the importance of designing and manufacturing a high-quality Instrument panel mold.

Let's start with the design of the Instrument panel mold. A good Automotive Mold Supplier will use advanced CAD/CAM software for mold design to ensure that every detail meets the automobile manufacturer's precise requirements. Our team of designers has rich experience and can design instrument panel molds that are both beautiful and practical according to customer needs.

Next comes the manufacturing process. As an Automotive Mold Supplier, we use high-precision CNC processing equipment and professional mold manufacturing technology to ensure that every component of the Instrument panel mold meets the high standards. Our manufacturing process strictly follows the ISO quality management system to ensure the quality and performance of each mold.

In the manufacturing process of Instrument panel mold, the selection of materials is also crucial. As an Automotive Mold Supplier, we select only the high quality materials, such as high-strength steel and durable plastics, to ensure the durability and reliability of our molds. In addition, we also use advanced surface treatment technologies, such as electroplating and spraying, to improve the corrosion resistance and aesthetics of the Instrument panel mold.

After completing manufacturing, our Automotive Mold Supplier will also conduct strict quality inspections. Each Instrument panel mold will undergo precise measurement and functional testing before leaving the factory to ensure that its dimensional accuracy and performance meet the automobile manufacturer's requirements. Our quality control team has professional testing equipment and rich experience, able to detect and solve any potential problems in time.

In addition to manufacturing high-quality Instrument panel molds, we as Automotive Mold Supplier also provide comprehensive after-sales services. Our technical support team is ready to answer customer questions and provide professional repair and maintenance services. Our goal is to ensure that every customer who uses our Instrument panel mold has a satisfactory experience.

Today, with the rapid development of the automobile industry, innovation is the key to the sustainable development of Automotive Mold Supplier. We continuously invest in R&D to explore new manufacturing technologies and materials to improve the performance of Instrument panel molds and reduce production costs. Our innovation is not only reflected in products, but also in services, and we are committed to providing customers with personalized solutions to meet their unique needs.

As automotive design continues to evolve, the design and functionality of Instrument panel molds are also constantly being upgraded. As an Automotive Mold Supplier, we keep up with industry trends and constantly optimize our product designs to adapt to market changes. Our Instrument panel molds can not only provide traditional display functions, but also integrate advanced technologies such as touch screen control and intelligent interconnection functions.

Search...

Search... English

English